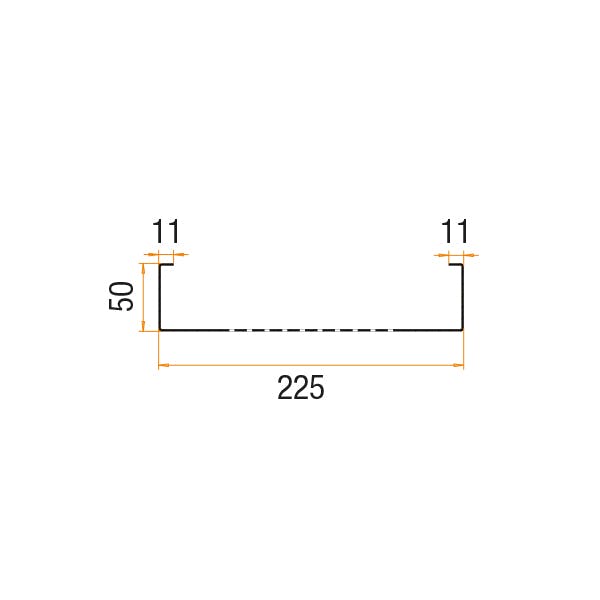

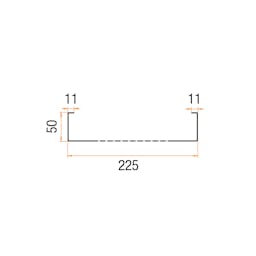

RY225mm

Steel sheet thermo stud for all circumstances, width 225mm

0,00 €/m

Total Price:

0,00 €

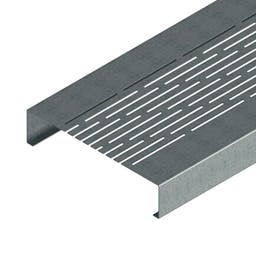

Thermo Profile is the perfect frame solution for elements and facades. It is made of environmentally friendly hot-dip galvanized steel sheet and is shaped into a gutter-shaped profile. The web of the thermal backbone is shaped so that the strength of the profile is the most advantageous shape when achieving thermal insulation values. In the Lundell-Profile thermal profile, the thermal bridge is cut with a special perforated structure and shape of the web. Other than Lundell perforation patterns do not meet the stated thermal values unless they have been separately tested.

Purpose and use

Thermal profiles are used in roofs, covers, floors, frames, and cladding of external and internal walls. Applications include residential buildings, industrial and commercial buildings, sports facilities, warehouses, and power plants, new construction, and renovation. Thermo profiles are usually used for load-bearing structures.

Material

Hot-dip galvanized steel sheet, steel grade S350GD + Z275 (EN10246)

Material thickness

0.75, 1.0, 1.25, 1.5, 2.0 mm

Cutting lengths

The profiles are manufactured according to the cutting list between 600-17000 mm and the length accuracies in the profile is +0 / -5 mm

Weight per square

3 - 7.8 kg / m2 thermal profiles and rails.

Web perforation

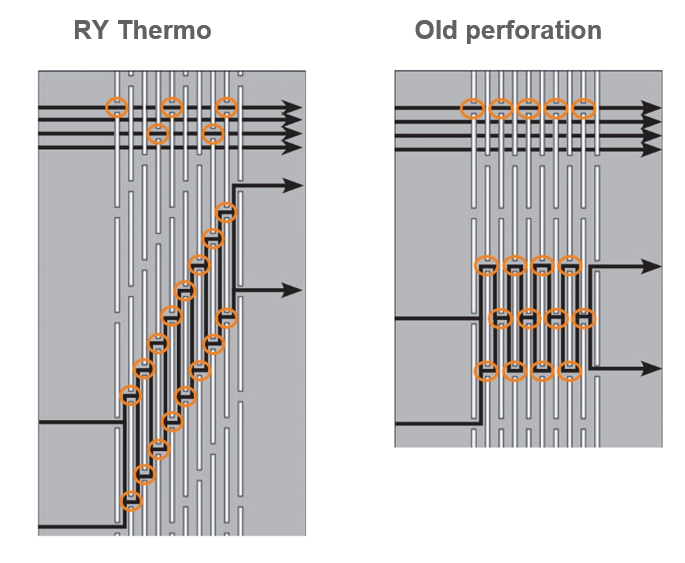

The formation of thermal bridges is prevented by a special perforation system in the web. The RY 225 web has 8 or 10 rows of thermal perforations. If the material thickness is 2mm, the maximum row line is 8. The ascending thermal perforation pattern is thermally the most efficient structure.

Attachment

The vertical profiles are usually installed between the horizontal top and bottom rails with a pitch of about 600 mm and fastened together according to the target plan defined by the designer. The fastening screws for the profiles must be as short as possible, eg EKO 16. The building boards are fastened according to the board manufacturer's instructions.

Installation does not require welding or grinding, and there is no need to cut the products on-site, because of the made-to-measure delivery. Individual machining of the thermal profiles can be made with an angle grinder, if necessary. Thermal profile extensions are always made as butt joints. Sealing strips are an accessory for thermal runners.

Sound insulation

Due to flanking sound transmission, the external wall structure must be completely cut off at the wall between the apartments. When an element meets the thermal insulation and tightness requirements set for it, the sound insulation requirements are also met.

Construction engineering and physics

The thermal conductivity of frame structures is clearly higher than that of insulation, therefore frame structures have a significant effect on the thermal transmittance of the wall structure and the temperatures of the structure. The thermo element weighs approx. 40-60 kg/m2. The deflection limit state of the element profiles is L / 150. Thermo profiles fastened to foundations/ concrete with eg Spike DL 6.3 * 51 through the profile. Thermo frames have their own angle brackets according to size.

E.g. fiber concrete slabs can be used as the façade panels of the structure, like ceramic tile surfaces or tin cassettes. There are two separate ventilation gaps between the façade panel and the insulation layer outside the load-bearing frame, in the middle of which there is a water and moisture-stopping structure, the so-called raincoat structure. For example, a raincoat structure consisting of a steel sheet directs the water away from the wall structure along the ventilation gap and protects the inner ventilation gap and insulation layers from wetting.

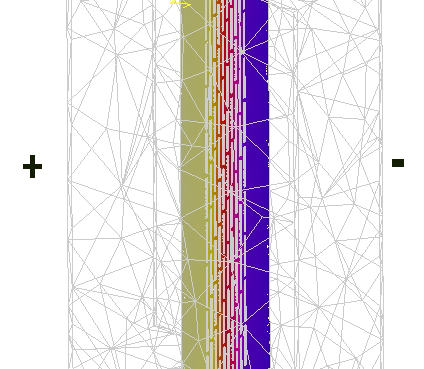

Thermal insulation and insulation

The nominal dimensions of the insulation fit the system. Cutting the insulation should be avoided. The insulation must completely fill the space reserved for them, the dimensions of the insulation must be + 5… 10 mm larger than the space reserved for them and the insulation must be tightly between the two surfaces. Note: Insulation of RY (C) profiles from the inside. The seam insulation completely fills the seam and the seals are completely attached to the element.

Airflows in the structure

Air flows, i.e. structural flows, occur through and within structures. They can be caused by temperature differences without movement, i.e. natural convection. The flows come and go from the structures on the same side.

The purpose of the vapor barrier is to prevent indoor air moisture from entering the structure. Indoor air moisture is transferred to the structure by water vapor diffusion or by air currents. The vapor barrier joints are overlapped by 150… 200 mm and taped or pressed between flat surfaces.

Packaging

Packed in pairs, ie 2 nested. Products of the specified sizes are manufactured and packaged according to the order and quantity list according to the order. Truck bundle 50-200 pcs, rim mounting, no protective plastic. Special bundles are packed according to the customer's wishes, eg according to element diagrams.

Storage

Allowed outdoor storage.

Recycling

100% recyclable material. If necessary, each profile can be removed and reused. The steel frame can be recycled at the end of the building's service life.

EPD

More environmentally friendly information on EPD calculations for load-bearing profiles.

More information and Dop

RY225mm

- 0,000€/ (alv 0%)

- Weight: /

- Weight: kg/

- Estimated delivery: week(s)